The history of scales

If you go back in time and show an old street merchant a digital scale, he will not know what to do. However, throughout history, the importance of scale to the economy is as important as it is today, which is why people have been working hard - and continuing to work - to obtain more accurate measurement results.

Ancient survey

Distance

Before the advent of standardized equipment, many measurements were based on a certain part of the body, such as the hands or feet-hence the "foot" of the Americans. When the standard ruler was introduced, these measurements became more accurate. Then, a known, repeatable standard will serve a specific geographic area.

Later, the two parties reached an agreement to produce a standard metal rod with two marks, which was very carefully made. This distance is designed to represent a fraction of one-tenth of the distance from the equator to the North Pole.

Recently, however, the definition of meters has become more accurate. It is defined as the distance that light travels in a specific, very small second. This distance is very standard and can be reproduced anywhere.

Time

Similarly, with the development of history, the measurement of time has become more accurate. The earliest measurements are based on the length of a day, or the amount of time between sunrise and sunset.

The invention of the sundial has achieved higher accuracy, which can divide the day into multiple parts. The specially manufactured candles are designed to burn at a steady rate, which provides a more accurate method of timekeeping.

Hourglasses, water clocks and pendulum clocks provide significant improvements. Recent clocks have been greatly improved using electronic devices such as tuning forks, quartz crystals and atomic clocks.

weight

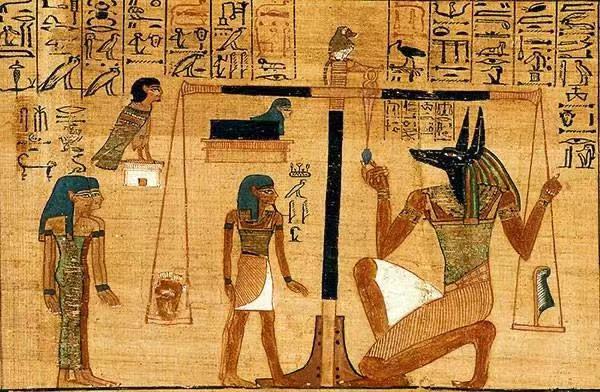

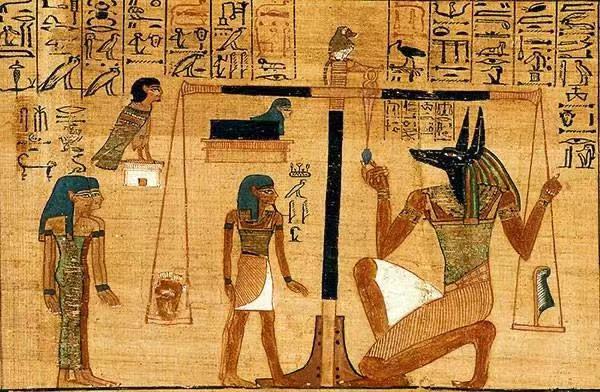

Weight measurement and scales follow a very similar path. Some of the earliest examples of weight measurement were a simple rod suspended with a rope in the middle. Each end is connected to a plate, and the product needs to be placed in one plate, while a stone representing a known weight is added to the other plate until the rod is balanced.

In fact, many of the earliest written histories we know emphasized the requirement of society to use "real weight."

The oldest balance is a basic balance, which consists of a lever and two weighing pans suspended equidistantly from the fulcrum. When an item needs to be weighed (such as a bag of gold coins), it is placed in one of the pans. Then add the known weight to the opposing plate and remove it from it until the lever is perfectly balanced in the horizontal position. By calculating the sum of the known weights, the weight of the object in another plate can be determined.

This system and similar variants were used until the late 1700s, when new weighing techniques were invented. However, these inventions are not as accurate as the electronic systems designed and perfected in the 20th century and the 21st century.

The Triple-Beam Balance

Recently, the more practical and complex three-beam balance was born. The device also uses a lever system in which the force on one side of the fulcrum is balanced with the force on the other side of the fulcrum.

However, unlike the original simple balance, the three-beam balance utilizes the concept that masses far away from the fulcrum of the lever produce more force on the lever than masses close to the lever.

Therefore, the three-beam balance does not need to apply the same weight on both sides of the lever to keep the balance in a balanced state, but balance the weight of the object on the other side of the lever by moving a smaller weight closer and away from the fulcrum. lever.

You have probably used this type of scale in a junior or high school physics science class.

Analog scale

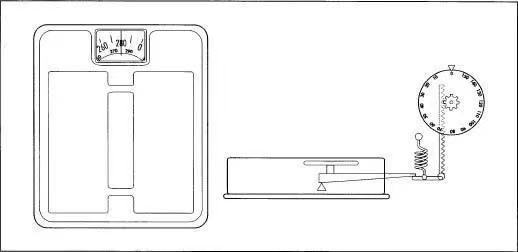

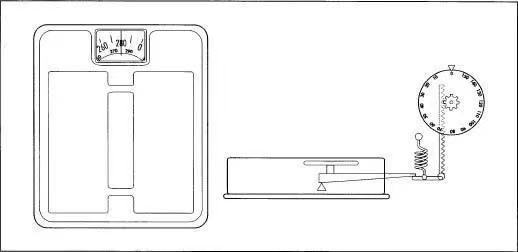

The next innovation is an analog scale called a spring balance, which relies on the concept that the force applied to the spring stretches the spring a known distance, and its "spring constant" is known.

The indicator on the spring will move up and down a certain distance relative to the gauge marked with various weight measurements. When the force of the spring is balanced with the force of the weighed object, the correct weight can be read.

The most common type of spring scale is the bathroom scale, which combines the force of four levers from each corner of the scale to stretch the spring and rotate the meter.

Analog scales in today's world

When the weight measurement does not need to be very precise, an analog scale is a perfect solution. They can determine a person's weight within 1 pound, or measure a portion of meat to within a few ounces.

However, they are not accurate enough for many industrial processes that require higher accuracy. Although the resolution of a spring scale may be 1 part in 100, industrial processes usually require a resolution of 1 part in 5,000 or higher.

Digital scale

Since its inception, digital scales have become the most accurate measuring equipment, and are by far the most widely used in industry. These electronic scales include platform scales, platform scales, floor scales, roller scales and cylinder scales.

The weight sensors used in digital industrial scales are called

Strain Gauge Load Cells. The load cell is a piece of metal whose shape causes it to bend in a very predictable way when subjected to force, like a spring. In addition, just like a spring, when the force is removed, the load cell returns to its original configuration.

Connected to the load cell are several

Strain Gauges. These resistors consist of folds of flat metal. When the load cell is bent and the strain gauge is stretched, the change in its resistance is proportional to the force acting on the load cell. The output signal of the strain gauge is sent to the ADC (Analog to Digital Converter), which outputs the final weight reading.

Ultra-precision scale

The resolution of the ordinary strain gauge digital scale is about one part in 5,000, and the accuracy is about one-tenth of 1%. However, this is still not as accurate as some industries require, which is why we have developed a new weighing technology called surface acoustic wave (SAW) and designed a new series of ultra-precision industrial scales.

These industrial scales use two semiconductor substrates and SAW transducers. When weight is applied to the scale, it generates a body wave that propagates between the transducers. The oscillation frequency of these devices is directly proportional to the weight on the weighing platform. By measuring digitally, we are able to provide a resolution of one in 100,000 and an accuracy of 1/100 of 1%.

These scales are particularly useful in situations where high accuracy is required, such as checkweighing, counting of small parts, accurate filling, flow monitoring, and polymer production. Pharmaceutical, chemical, paint and many other industries all rely on this ultra-precision technology.